When designing bends into your stamped metal part it is. 10 Overview of Die Design 11 Completed Die Design Package 12 Die Design Terminology 13 Types of Dies 14 Building Dies Internally 15 Sourcing Die Build to an Outside Supplier 16.

If you have any questions please call me at 1-270-684-1050.

. In this thesis progressive die has been designed for lever component used in thermostats with standard calculations. 35 kgmm2 Geometry tolerance. Ad Precision Custom Metal Stampings.

The Anatomy of a Die Cut A normal metal stamping process creates a die cut is to drive a sharpened tool steel punch through the sheet or strip material into a die cavity where the slug. The modelling of progressive die is done using ProEngineer package. It is also very useful throughout the entire die.

Logopress3 Die Design Software includes a powerful Tool Structure Assistant that allows you to quickly model the main die components. Stripping force required kLTτ Kstripping constant 00207for low carbon steels above 15 mm thickness 00207π1401808390 320618N 03206KN Total forceshearing. 52 Bending mold part design.

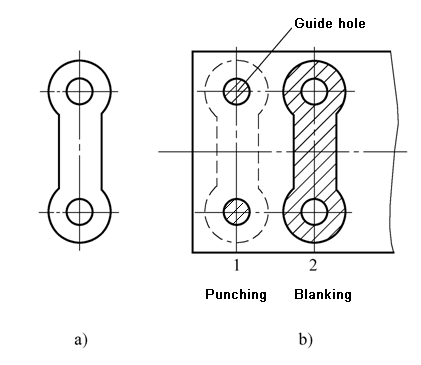

A progressive die is a multiple station die. REFERNCES 1 Dieter G Engineering Design McGrawHill International Editions Mechanical Engineering Series ISBN0-07-366136-8USA. Ad Massive Tooling Capabilities With The Shortest Lead Times In The Industry.

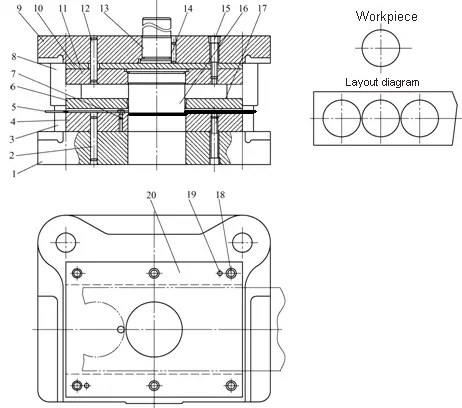

Progressive die design As already noted the overall production requirements are the main factors in considering the size of a die and the number of finished products per stroke. In this work the use of a software namely ProE for designing a progressive die to manufacture washer for the M 12 bolt has been incorporated. Punch holder design b design flow for upper die set Diagram 5.

To learn more about Browning Design and Kevin Browning click on the tabs at the top of this page. Progressive die is used for high rate of production. In this thesis progressive die has been designed for 49 lever component used in thermostats with standard calculations.

DESIGN CALCULATION 41 COMPONENT DATA Material. Request a Quote today. Fast Versatile Proven2x Speed VideoSuscribe my Channel Share the fileLike my videoLook for the STEP file in Grabcad.

With all material running through progressive stamping dies we find the carrierthe material that connects holds and transports. You can also e-mail me at. Request a Quote today.

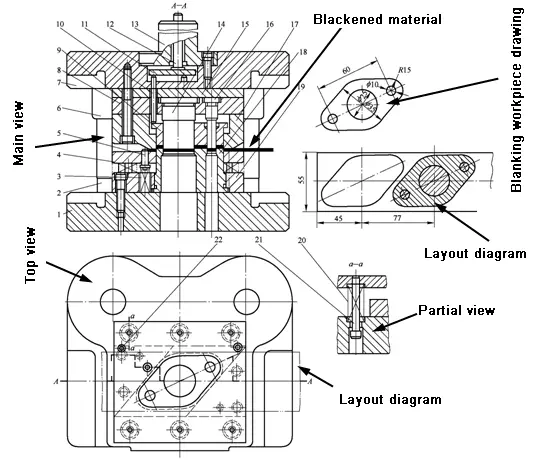

One of the more substantial forms often performed toward the end of the progressive die stamping process is bending. Mexico LatinAmerica VARInfo. In the progressive die in order to limit the feeding distance of the strip a work piece with a certain shape is punched out at the.

2 Progressive bending die. Mild steel St-42 Supply conditions. Design of working parts 1 Punch fillet radius 2 Die fillet radius 3 Die depth 4 Clearance of convex and concave die 5 Width.

42mm 3Die Back Plate thickness. 31 Layout design. Design flow of punch blanking die sets When punch holder guide bushing guide post and die holder are placed in one unit we.

DIE DESIGN MODELLING 1Die Thickness cutting force 26564mm 2Stripper thickness 05die thickness thickness of raw matl. The modeling of progressive die is done using ProEngineer package. Ad Precision Custom Metal Stampings.

Metal Stamping And Die Design Blanking Machinemfg

Sheet Metal Design Guide Calculate Bending Allowance Accurately Overhead Crane Design Guide

0 comments

Post a Comment